Processing High Purity Urethanes

High purity urethanes formulated for applications such as cable over-molding, cable connectors, cable splicing, electrical potting, and others require highly pure forms of urethanes to perform adequately.

From a meter, mix perspective the process equipment requires rethinking the standard design such that the integrity of the material is not degraded. Process variables such as thermal management, vacuum, materials of construction and other considerations will change the approach to the design.

With many unfilled, high-purity urethanes an excellent method of processing is the gear pump. It is simple, accurate, reliable, versatile and easy to maintain. It provides metering accuracies in excess of those specified by the adhesive manufacturer. Gear metering pumps are used in all areas of chemical processing including flow control and metering, and dosing.

By combining two precision gear meters, very accurate and repeatable ratio tolerances are achieved, typically within one percent by volume. The metering pumps form the heart of the system.

There are three basic functions in the meter, mix system; the prep tanks, the metering, and the dispense section. Each function prepares the material for the next operation.

Feed or prep tanks can provide heating, agitation, and vacuum degas which prepares the material for the metering section. The metering section then establishes the ratio and flow rate or shot size followed by the dispense section.

FEED SYSTEM

With the high-purity urethane, heating and vacuum degassing are necessary to prevent moisture contamination and crystal formation. Both of which will cause degradation of the urethane. Heating in the Ashby Cross system is done with electric resistance coils imbedded in thermal transfer compound located outside the bottom of the tank. A thermocouple senses temperature and feeds a proportional controller. This method is highly reliable, accurate and eliminates temperature overrun. Typically a local analog probe with display is mounted through the tank wall providing actual material temperature.

Top mounted agitators move material gradually within the tank during degas and heating to provide uniform degas and temperature. Vacuum pumps can be dedicated and located on-board to provide the necessary vacuum service. In some instances nitrogen is used in place of air to ensure moisture-free environment.

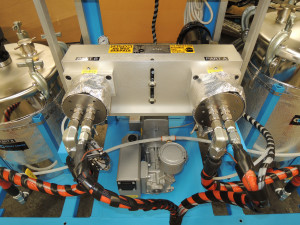

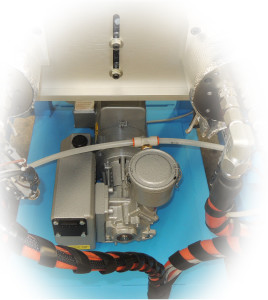

On-board vacuum pumps provide a dedicated

Degas source to the tanks

Metering

This is the section of the system that proportions the material in the specified volume ratio. In this case, two gear pumps, one for each side, will receive prepped material from the Feed System. Gear pumps are designed to produce a specific output per revolution. For example, combining pumps with different output such as 10cc/revolution and 5cc/revolution the system will produce an overall ratio of 100:50 by volume. To achieve other ratios, for instance 100:33, a combination of pump sizing and different relational speeds will produce the result.

With highly sensitive urethanes there is a need to maintain a uniform elevated temperature to prevent solids from developing. Therefore gear pumps are individually heated and controlled to maintain material integrity.

Heated gear pumps

The design includes wet cup reservoirs which surround the input shaft packings and seals. These reservoirs help maintain seal integrity and prevent material from leaking into the shafts area. By lubricating the shaft areas material leakage is prevented.

One of the major benefits of gear pump metering is the simplicity of the operation. Very few moving parts, self-bleeding, accurate metering, and infrequent maintenance combine to form a reliable simple system.

Dispense

From the metering section material flows through the dispense hoses to the mix/dispense valve. Here the materials are combined in the static mixer. The mix dispense valve can be static or dynamic depending on the nature of the adhesive and the mixing required.

The NPH-5000 valve features a snuff-back design, adjustable packings and drip-free operation. The valve makes use of the standard bell-mouth static mixer.

The DYNA-STAT® 6000 valve is available with pneumatic motor drive or electric motor drive. The drive selected will depend on the application. Electric motor drive has digital control with speed feedback console for repeatable and adjustable speed control. The air motor drive uses a pneumatic motor to drive the disposable mix elements.

– Ashby Cross Company